The invention of Pneumatic Tube System was a stepping stone of mankind towards modernization into the 21st century. The technology played a pivotal role in establishing communication between major government and financial institutions throughout the 20th century. As the years passed, Pneumatic tubing technology diversified its applications to various other fields.

The primary benefit of this cutting-edge technology is being prevailed by the healthcare facilities and large hospitals. Various other industries have now recognised the importance of this pioneering technology and its application is ever on the rise.

In this blog, we will have a look at the evolution of the primitive pneumatic tube system over the years into an everyday urban necessity. We will also discuss the diverse non-healthcare applications of Pneumatic tubes in today's society.

The story of Pneumatic Tube System

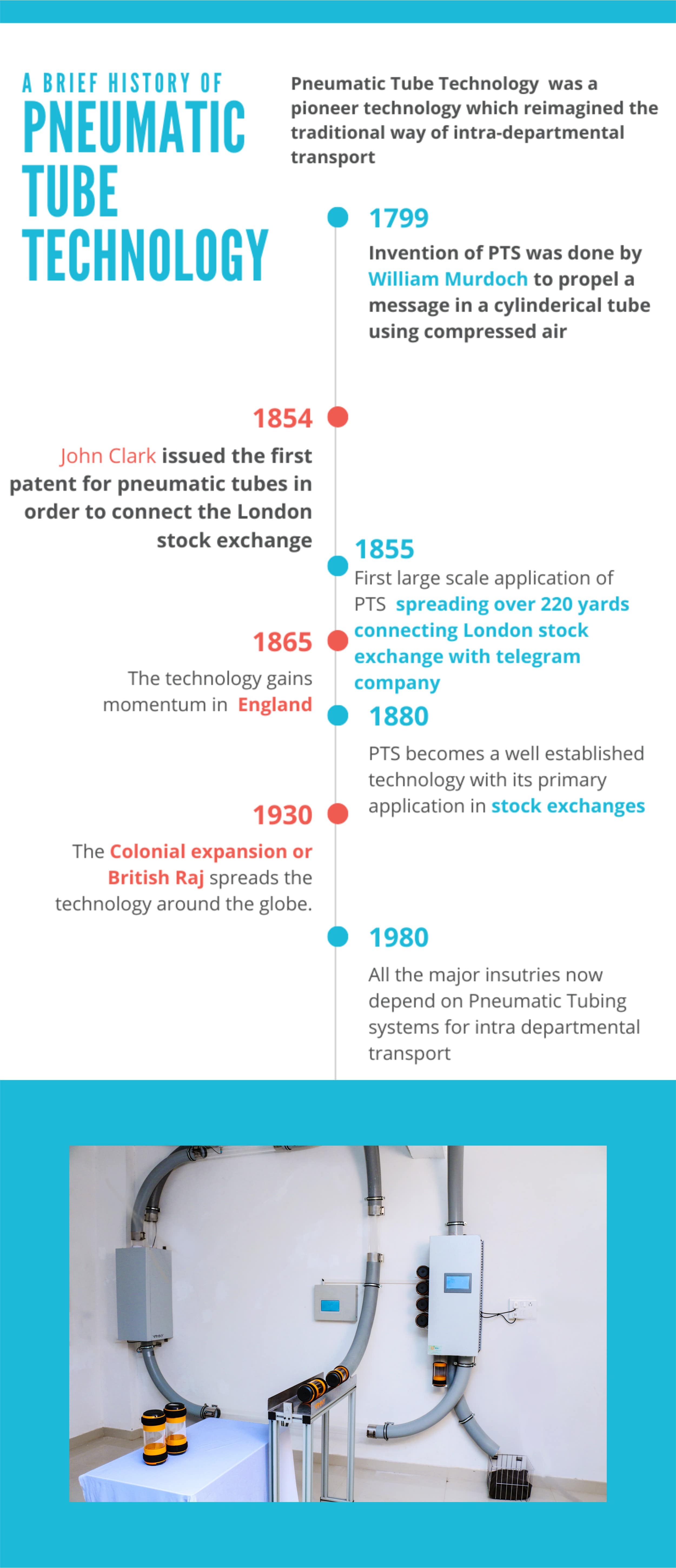

A timeline explaining the evolution of

Pneumatic Tube System over the years

A timeline explaining the evolution of

Pneumatic Tube System over the years

1799-Invention of Pneumatic Transport System

No breakthrough came after the invention of vacuum in 1660 until one British scientist named William Murdoch's invention. The Shoot System as we know it was invented by him in 1799 while trying to demonstrate the impact of the magnetic field in a vacuum.

Murdoch noted the swiftness with which a cylinder would travel across a pipe under the influence of negative pressure or vacuum. He used the cylinder to carry messages within his laboratory.

1854-Patent of the technology

J Clark in 1854 was the first to patent the pneumatic tube technology after realising the potential of the science.

1855-London Stock Exchange (LSE)

The mid-19th century was a turning point in the financial sector with an increasing number of companies going public with an IPO. This required swift transportation of messages between the London Stock Exchange with Electric telegraph company.

The busy streets of London did not permit the ease of communication. J Clark was quick to connect the LSE with the telegram service using pneumatic tubes and eliminating the need for road travel.

Shoot System was in its golden era during the

mid-19th century

Source: Adobe Stock royalty-free images

Shoot System was in its golden era during the

mid-19th century

Source: Adobe Stock royalty-free images

1865-Pneumatic Transport System is now a must for Stock exchange

Pneumatic tubing systems were a necessity for stock markets all around the world including some big names like Birmingham, Manchester and even New York stock exchange.

1880- Pneumatic tubes a well-established technology

By 1880 there were over 22 miles of pneumatic tubes in London itself. British scientists were now trying to apply their knowledge of vacuums to Railways and trying to build underground metros to work on the principles of maglev and vacuum. This technology failed at that time but now is being worked on again by Elon Musk’s Hyperloop following similar principles.

It was around this time the secret royal society of Great Britain was also using Pneumatic Tubes to deliver secret information. This was the safest way to commute without worrying about messages being intercepted.

1930-Colonial expansion spreads the technology to the world

The British Raj was at its peak during the mid-20th century spreading from the east to the west. Since Pneumatic Tubes were British technology, their use spread globally.

1980-All major industries require Pneumatic Transport System lead by healthcare facilities

Before the turn of the 21st century, Pneumatic tubes demand in healthcare had exceeded the banking and finance sector. Stock exchanges and Cash receipts were being carried out heavily with Shoot System. The major hospitals required quick transport of lab samples and medicines from the testing centre to the patients' bed. A well-connected Shoot System was an essential prerequisite for major hospitals all across the globe.

Modern-day applications of Pneumatic Transport System

Pneumatic Tube System have become an integral part of all major healthcare facilities and hospitals. In this blog, we take a glimpse at the various non-healthcare related benefits. Pneumatic tube technology plays a critical part in locomotion of dangerous substances that cannot be transported easily by humans. Besides, government facilities like the CIA which handle top-secret information and cannot risk being tapped also apply the Shoot System technology to date.

Leading applications of Pneumatic Tube System

around the world

Leading applications of Pneumatic Tube System

around the world

Banking and finance sector

Banks and many other financial institutions carry out transactions of large amounts multiple times within a day. This requires an efficient and reliable mode of transportation to carry the large sums of money, as well as the receipts of such large transcripts, need to be delivered securely.

There needs to be a direct line of communication between the cash counter and the branch manager for the transport of such highly sensitive transcripts and cash receipts. All such intra-bank transactions are carried out with the help of secure Pneumatic tubes.

Laboratories

Scientific community carries out experiments regularly in their laboratories. These experiments are carried out at a different site and the results are observed elsewhere. There needs to be a strong line of commute between the site of the experiment and the site of observation.

In experiments involving radioactive isotope decay studies, it is humanly impossible to carry the experiment without Shoot System.

This is carried out using Pneumatic tubes which are a huge blessing for the scientific community.

Pharmacies

One of the leading paramedical industry is the pharmaceuticals. Drug manufacturing and distribution is a key part of these pharmacies. The process of drug production on large scale is a complicated one. Test samples regularly need to be transported within the laboratory.

The wide scale applications of Pneumatic tubes helped to overcome this frequent transport of pharmaceuticals. Large scale production of medicines cannot be imagined without Shoot System technology.

Livestock and dairy industry

India is the largest producer and consumer of milk and its products in the world. This makes the dairy industry one of the most thriving and profitable sectors of India.

Applications of Pneumatic Tube System is quintessential in such industries. Industries dealing with livestock and their products require a constant transportation facility for moving various test samples and dairy products in small quantities. Pneumatic Transport System application ensures proper utilisation of manpower in dairy industry.

Pneumatic tubes are used in several departments in a dairy. Namely,

- The Milk collecting centre

- Milk processing sector

- Various segments of dairy products processing sectors

- Quality and standard managing unit

- Packaging unit

By coordinating and connecting all of these units in a dairy, Pneumatic Transport System has revolutionised and modernised the traditional dairies to make them much more efficient.

Factories and large-scale plants

Large factories and production units deal with manufacturing tons of goods daily. They need to be highly efficient to meet the deadline criteria and at the same time meeting the set quality criteria.

Connecting the site of manufacturing to the site of packaging is quintessential at such places. There also needs to be a line of transit between the manufacturing with the Research and development team who regularly carry out tests for better quality control.

Nevertheless, all locomotion is carried out most effectively by Pneumatic Transport System.

The factories, power plants and large-scale industries have recorded encouraging results after application of Pneumatic Tube Technology. The impact of a simple and straight forward Pneumatic Tube System can provide a huge boost for any business.

Factories using Pneumatic tubes

Source: Royalty-free images on Google- adobe

stock photos

Factories using Pneumatic tubes

Source: Royalty-free images on Google- adobe

stock photos

Transport of Hazards- Iron furnaces, moulting irons, radioactive decay studies

Industries dealing with moving of humanly hazardous intermediates within their premises essentially work on Pneumatic tubes. Manufacturing of metals using hot furnaces which requires the immediate moulding need to be transported quickly. Iron clads and manufacturing of other metallic goods need a well-equipped Pneumatic transport system.

NASA, CIA & other government facilities

Transport of sensitive information which cannot be encrypted and sent using computers for the fear of getting tapped are sent using Pneumatic Tube System. Indian as well as foreign government agencies essentially use Pneumatic Tube System till date.